Weekly Delivery

Report Module Guide: Weekly Shipping Report

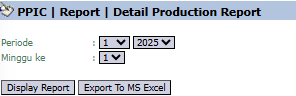

Module Location

Sales > Reports > Shipping Reports > Weekly Shipping (Note: The title in the system indicates this report is related to PPIC | Report | Detail Production Report)

Module Objective

The Weekly Shipping report module is used to generate a comparative report between the shipping Plan and the Actual realization within a single week. This report is an important Key Performance Indicator (KPI) for monitoring the on-time performance and fulfillment of the shipping schedule by the logistics and production teams.

1. Report Parameters

The main page of this module is a simple form for selecting the report period.

Here is an explanation for each parameter:

-

Period:

-

Select the month and year of the report period you wish to see.

-

-

Week number:

-

Select the week number within that month that you want to analyze (e.g., week 1, 2, 3, or 4).

-

2. Steps to Generate the Report

Step 1: Set Report Parameters

Select the Period (month and year) as well as the Week number to be analyzed.

Step 2: Generate the Report

After the parameters are set, click one of the two buttons at the bottom:

-

Display Report: To preview the comparison report directly on your screen.

-

Export To MS Excel: To download the report data in an Excel file format.

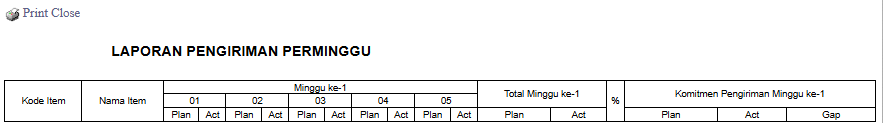

3. Reading the Weekly Shipping Report

The generated report will present a detailed comparison between the plan and the realization.

Report Explanation: This report is designed for in-depth Plan vs. Actual analysis.

-

Daily Breakdown: The Week 1 section details the Plan and Act (Actual) comparison for each working day (dates 01 to 05).

-

Weekly Total & Commitment: The Total Week 1 and Shipping Commitment Week 1 columns summarize the performance for the full week.

-

Analysis Columns:

-

%: Shows the percentage of shipping target achievement.

-

Gap: Shows the difference or gap between the planned quantity and the realized quantity.

-

Tips & Important Notes

-

This report is a crucial performance measurement tool for the PPIC (Production Planning and Inventory Control) and Logistics teams.

-

Use this report to identify delays or problems in fulfilling the shipping schedule early and to take corrective action.

-

The 'Plan' data is likely pulled from a forecast or master production schedule, while the 'Act' data is pulled from actual shipping documents like Delivery Orders.

No comments to display

No comments to display